The Gears of Grategy®: Innovating Air Filtration Workplace Culture

May 14, 2025

In the wake of the pandemic, the air filtration industry faces a unique set of challenges and opportunities within an increasingly employee-driven and competitive market. The adage, "Times are changing," rings truer than ever, marking a definitive shift from the “good ole days” of 2019. This article will give air filtration professionals the strategies needed to keep their top talent from becoming someone else’s.

Leveraging my extensive experience of over a decade in industrial sales, including a seven-year stint in the welding industry, I've observed the distinctive practices that catapult organizations to best-in-class status. A key component of these company’s success has been the power of blending Gratitude with Strategy—what I've coined as Grategy®. Implementing Grategy cultivates a work environment where excellence is not just pursued but flourished, and loyalty is deeply rooted.

To demystify this approach and revolutionize our understanding of workplace culture, I've developed the "Gears of Grategy." Far from being a mere set of tools, this innovative framework is designed to attract and retain top talent by nurturing a workplace culture anchored in positivity, recognition, and personal growth – and it all starts with YOU.

Integrating these gears into your air filtration business signifies a profound commitment to cultivating a culture that doesn't just attract good people but fosters their development and contribution towards your shared success. I'd like to hear how these gears have transformed your organizational culture and propelled your company forward. Without further ado, here they are.

The Six Gears of Grategy®

- #Attitude: The Foundation: Above all else, your attitude matters. Beyond simple optimism, it's about embracing change as an opportunity, viewing innovation as essential, and committing to continuous improvement. Your perception and response to shifts in this dynamic sector greatly influences your professional growth and leadership potential.

The air filtration field's rapid evolution, marked by new technologies and regulations, demands an adaptable mindset. Seeing these changes as chances for growth, rather than obstacles, sets you apart and fuels your drive for innovative solutions. Resilience, fostered by a positive outlook, is key. It allows you to bounce back from setbacks and face challenges with confidence. Such an attitude is critical in a sector impacting public and environmental well-being. Embracing every situation as a learning opportunity prepares you to tackle both current and unforeseen challenges creatively.

Ultimately, adopting the right mindset is indispensable. Change, while intimidating, opens doors to growth and innovation. Your choice of attitude is totally up to you. Choose wisely.

- #Appreciation: The Personal Touch of Gratitude: The second gear in the Grategy® model is appreciation, where you embrace gratitude on a personal level. My venture into gratitude began in 2009, a pivotal shift that has steered me through challenging times, including the recent pandemic. This journey has revealed that gratitude is more than positivity; it's a mindset that prompts you to find the good in every situation, backed by research showing its power to rewire your brain towards focusing on the positives, enhancing mental and physical health.

Making gratitude a daily practice helps you consistently recognizing the positives, even in adversity. This habit not only benefits you but also those around you, encouraging a deeper appreciation for the contributions of each member within your professional circle. Genuine acknowledgment of others' efforts enriches interactions, strengthening your leadership by demonstrating the importance of everyone’s role. This attitude of gratitude is not just beneficial—it's transformative, paving the way for a fulfilling professional and personal life.

- #Access: Open Doors, Open Minds: This gear revolves around cultivating leadership that is not just approachable but genuinely accessible, fostering an environment where every member feels valued and their voice heard. It's about dismantling the traditional barriers between management and employees, thereby not merely opening doors, but also broadening minds.

Access transcends mere physical availability; it encompasses creating avenues for both personal and professional advancement. This involves implementing comprehensive training programs and providing resources that enable individuals to thrive, both within and beyond the confines of the workplace. When members feel supported in their growth, they are inspired to contribute their best.

The era of the one-size-fits-all approach to company culture is behind us. The contemporary workplace demands flexibility to accommodate the diverse needs and aspirations of its members. Leaders are encouraged to be not just physically present but actively engaged, seeking out feedback, and staying attuned to the workforce's evolving needs through proactive engagement methods like "stay" interviews. These discussions are gold mines of insight into the ambitions and concerns of employees, offering a proactive means to address potential issues and mitigate turnover risks.

By championing open communication and ensuring accessibility, you lay the foundations for trust and loyalty, which are crucial for retention. The Access gear guarantees that dialogue moves fluidly in both directions, cultivating a transparent and supportive culture that boosts engagement and propels the organization towards success.

- #Applause: Recognizing and Celebrating Success: In the air filtration industry, recognizing achievements, both big and small, plays a pivotal role in driving progress and innovation. This is where the concept of #Applause becomes vital. Expressing gratitude, whether through verbal praise or a thoughtful handwritten note, not only creates memorable moments but also cements a culture of appreciation within your organization. Celebrating the milestones in the development of air purification technologies or acknowledging the dedication behind meeting stringent environmental standards fuels motivation and uplifts team spirit.

Personalization in recognition is key. Understanding what resonates with each member of your team, perhaps through preferences noted on an "All About Me" sheet, enhances the impact of your appreciation. Remember, there is no one-size-fits-all approach when it comes to recognizing the efforts of your people.

Moreover, recognition doesn't need to be extravagant. Simple gestures, such as a sincere "thank you," a personalized note, or a highlight in the internal newsletter, can significantly brighten someone's day. Encouraging peer recognition further strengthens team bonds, fostering a sense of unity and shared purpose.

In essence, the act of acknowledging and celebrating success is not just about boosting morale; it's about reinforcing the behaviors and innovations that lead to cleaner air and healthier environments. By integrating #Applause into your organizational culture, you highlight the importance of every achievement and contribution, big or small, in advancing the industry’s collective mission.

- #ActsOfService: This fifth gear means extending the impact of your expertise in air filtration beyond the confines of daily tasks. It involves embedding corporate social responsibility and volunteerism into your core operations, significantly contributing to the health and well-being of communities and the environment. This initiative aligns perfectly with the deep-seated motivations that drew you to the air filtration industry: the desire to improve public health and protect the planet.

By participating in projects that enhance air quality, promote environmental sustainability, or educate the public about the benefits of clean air, you live out the values that attracted you to this field. Demonstrating to your team how their work transcends ordinary responsibilities to contribute to a grander mission fosters a profound sense of purpose and belonging.

This dedication to service transcends basic job functions and financial rewards. It's about showing the world the significant impact your industry can have. Through acts of service, you not only bolster team unity and attract like-minded professionals but also develop a brand that stands for meaningful change. For you, as part of NAFA, integrating acts of service into your ethos is crucial for inspiring continued innovation and leadership in air filtration, making every effort count towards a healthier, sustainable future.

- #Accountability: Ensuring Alignment and Continuous Improvement: In the air filtration industry, #Accountability is crucial, serving as the cornerstone that ensures every effort contributes to your overarching goal: cleaner air and environmental protection. It's about more than just meeting benchmarks; it's a commitment to continuous improvement and adaptation. By implementing Key Performance Indicators (KPIs) specific to air quality enhancements and operational efficiencies, you measure the tangible impact of your work. However, accountability in this field goes beyond numbers; it's about being ready to evolve your strategies and technologies in response to new research and regulations.

This dedication to progress ensures that the pursuit of excellence is a never-ending journey. What may be effective today could be improved tomorrow, highlighting the necessity for ongoing adaptation and refinement. In the dynamic world of air filtration, accountability means embracing change and seeking ways to advance industry methods and outcomes continually.

By fostering a culture that values persistent growth, you encourage both leadership and team members to take ownership of their contributions to the mission. This approach doesn't signal an endpoint but rather propels the industry forward, ensuring that it remains at the forefront of environmental health and safety. Accountability, therefore, is not just a principle but a practice that reinvigorates your collective efforts, driving you towards innovation and excellence in every aspect of your work.

Why the Gears of Grategy® Matter

In the air filtration industry, the Gears of Grategy® are foundational to building a culture that not only attracts but also retains the brightest minds. At a time when professionals seek fulfillment beyond financial rewards, these gears offer a structured approach to fostering an environment that values, respects, and nurtures its talent. For NAFA members, embracing the Gears of Grategy® equips you to empower your teams, elevate performance levels, and forge a legacy of a positive workplace culture.

These gears are a testament to a commitment towards excellence. They envision a workplace where every individual feels valued, heard, and integral to the collective mission of improving air quality and environmental health. In the intricate and ever-evolving landscape of air filtration, adhering to the Gears of Grategy® shines a light on the path for leaders aspiring to steer their teams with compassion, integrity, and relentless dedication to excellence.

As we chart our course through the complexities of today's business environment, the Gears of Grategy® emerge as beacons for those determined to redefine standards of workplace excellence. They are a call to action for setting a new benchmark in the air filtration sector, emphasizing the importance of a workplace where innovation thrives, and every team member's contribution is recognized. If you're inspired to elevate your workplace using these principles, it's time to connect and embark on a transformative journey together.

Author: Lisa Ryan is the Chief Appreciation Strategist and Founder of Grategy where she is pioneering workplace culture transformation through the power of gratitude and strategy. To learn more, please visit LisaRyanSpeaks.com.

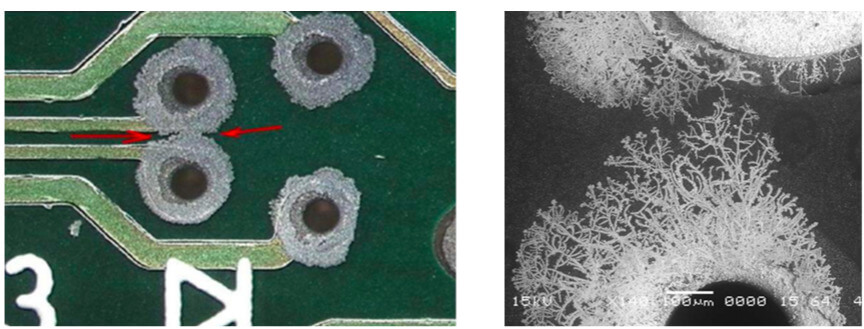

FIGURE 1: A visual representation illustrating:

First Image: Copper Creep Corrosion- Photographic and electron microscopic images depicting the degradation of copper plating on printed circuit boards as it transforms into copper sulfide. This progression extends across the boards, resulting in electrical shorts between nearby features and ultimately culminating in system failures 4, 6.

Second Image: Silver Termination Corrosion- Electron microscopic depicting the silver terminations in surface-mounted components resulting in the degradation of silver metallization and the eventual occurrence of open circuits in components such as resistors 5, 6.

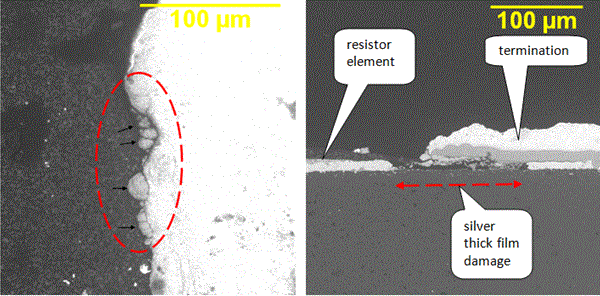

Air Handling in Data Center

Data centers utilize air filtration systems that differ from conventional setups. They incorporate specialized units like the Computer Room Air Conditioner (CRAC) / Computer Room Air Handler (CRAH), housing filters along with fans, and cooling coils to ensure consistent room filtering. They are specifically designed to cool and regulate the temperature and humidity in the data center. Additionally, a standard Air Handling Unit manages incoming air from outside. Figure 2 illustrates the air handling system within a data center.

FIGURE 2: Illustration depicting the air handling system within a data center

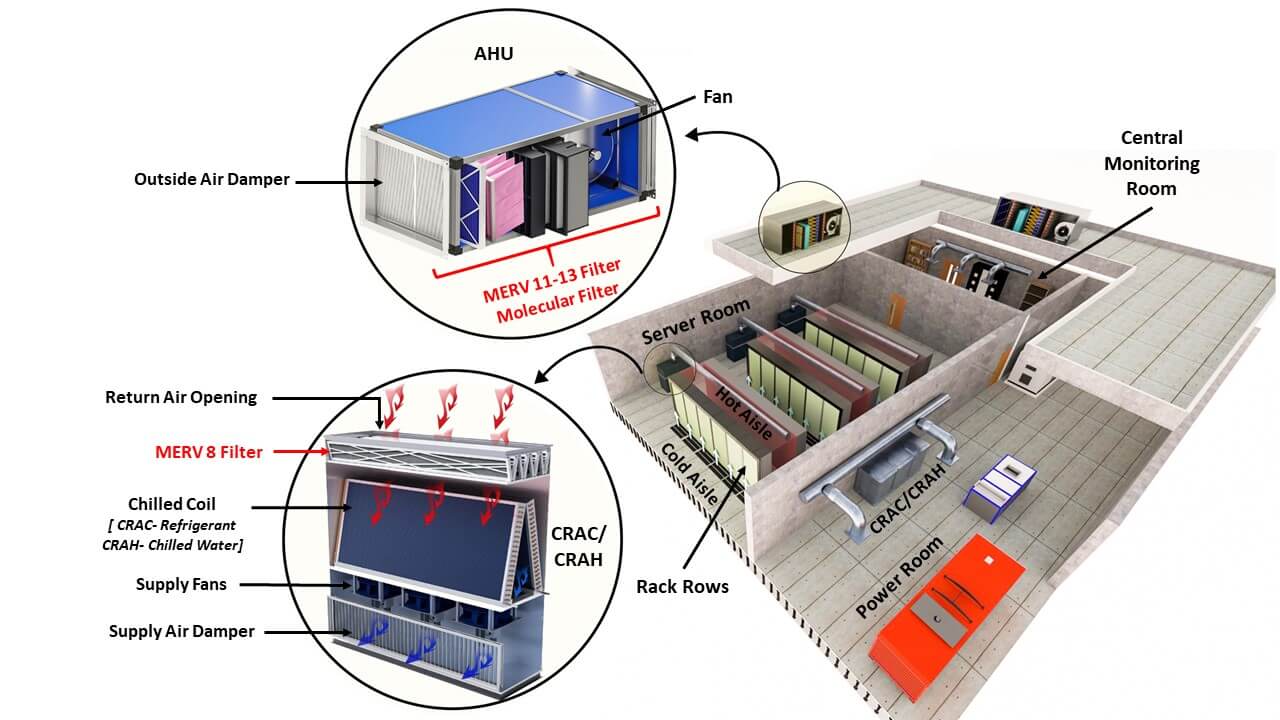

Mitigation of Particulate Contamination

Effective particulate contamination control can be achieved with commonly available filters. ASHRAE recommends continuous room air filtering using MERV 8 filters, and suggests higher filtration levels like MERV 11 or MERV 13 for incoming air. Due to the energy-intensive nature of data centers, filters with low pressure drop and high dust holding capacity are preferred. Recently, Nanofiber filters, featuring thin layers on supportive substrates, have gained attention for their surface loading, which allows for effective dust accumulation. While in contrast, traditional filters experience depth loading over time, leading to blockages and increased pressure drops3.

Mitigation of Gaseous Contamination

To manage gaseous contamination, specialized filters called molecular filters are used. In data centers situated in areas with high gaseous contamination, it is recommended to deploy molecular filtration systems for both incoming and internal air. Table 1 outlines gaseous elements present in the environment, highlighting potential threats to data center components if they exceed specified control limits.

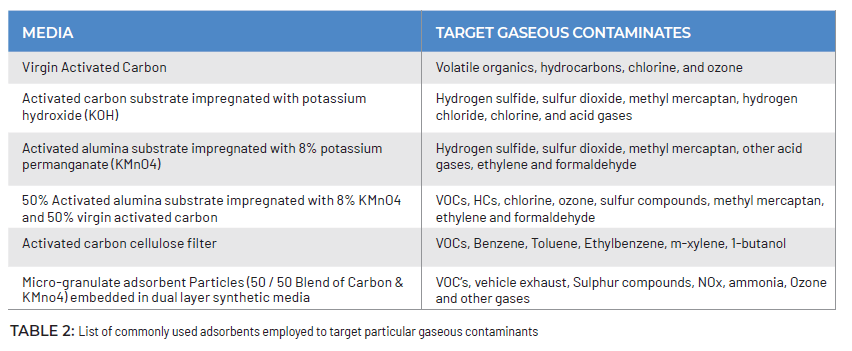

TABLE 1: Gaseous elements present in the environment and their impact on data center components when surpassing specified control limits6.

Molecular filters utilize adsorbent or chemisorbent media designed to capture gaseous contaminants. Depending on system design and contaminant characteristics, the media can be in the form of pellets, granules, or modules. Adsorbents, attracting molecules through forces like van der Waals forces, effectively capture low concentrations of non-reactive gases such as volatile organic compounds (VOCs), odors, and hydrocarbons. Activated carbon, with its extensive surface area, is a commonly used adsorbent capable of adsorbing a wide range of gases.

Chemisorbents chemically react with contaminants to form stable compounds, suitable for removing high concentrations of reactive gases like acids, bases, oxidants, and corrosives. Impregnated activated carbon, treated to enhance reactivity, is a frequently used chemisorbent in molecular filtration7. Some molecular filtration systems optimize performance by combining adsorbents and chemisorbents. For example, a system may use an adsorbent layer followed by a chemisorbent layer to eliminate both VOCs and acids from the air stream. Table 2 outlines various adsorbents widely used to address specific gaseous pollutants. Numerous ongoing studies are being reported aimed at developing new adsorbent materials with significant adsorption capacity.

When selecting a molecular filtration system for a specific application, several factors come into play, including the type and concentration of gaseous contaminants, the required airflow rate and pressure drop across the system, the desired removal efficiency and outlet concentration of contaminants, the operating temperature and humidity conditions, as well as the available space and budget for system installation and maintenance.

References:

- Steve Greenberg, Evan Mills, and Bill Tschudi, Peter Rumsey, Bruce Myatt, Best Practices for Data Centers: Lessons Learned from Benchmarking 22 Data Centers, 2006, ACEEE Summer Study on Energy Efficiency in Buildings, 3, 76-87.

- Henry C. Coles, Taewon Han, Phillip N. Price, Ashok J. Gadgil and William F. Tschudi, Air Corrosivity in U.S. Outdoor-Air-Cooled Data Centers is Similar to That in Conventional Data Centers, 2011, Lawrence Berkeley National Laboratory, 1-29.

- ASHRAE, Gaseous and Particulate Contamination Guidelines For Data Centers, 2011

- What is Creep Corrosion and How to Avoid or Mitigate It? (URL: https://knowledge.ni.com/KnowledgeArticleDetails?id=kA00Z000000kIpsSAE)

- Craig Hillman, Joelle Arnold, Seth Binfield, Jeremy Seppi, Silver And Sulfur: Case Studies, Physics, And Possible Solutions,2007, DfR Solutions, 1-13.

- Chris Muller, What’s Creeping Around in Your Data Center?, 2010, ASHRAE Transactions, 1-15.

- Jones, G., Rohrbach, R., Unger, P., Bause, D. et al., Wicking Fiber Chemisorption for Air Quality Improvement, 1997, SAE Technical Paper 970555,1-7.

Author: M.S.Giri Nandagopal, PhD, Product Development Engineer, Excelair Filters, Century Mechanical Systems Factory LLC