Installation, Tensioning & Maintenance of V-Belts

Introduction to Power Transmission Belting used in the HVAC-R Industry

Types of Power Transmission

There are various types of power transmission devices commonly used in industry today. Among them for example, chains, gears, v-belts and synchronous belts are widely used. The focus of this exercise will be a general introduction to rubber power transmission belts and more specifically, those v-belts and synchronous belts used in the Heating, Ventilation, Air Conditioning and Refrigeration (HVAC-R) industry.

Power Transmission Belting

The primary function of a belt is to simply transfer rotation from the powered driver pulley to one or more driven pulleys. The belt must be designed and capable of transferring this torque efficiently and reliably. Generally, the most economical component in the system, belts can also act as a “safety fuse” by slipping or breaking under a peak or shock load situation, such as when a drive becomes jammed by debris, which can protect the more expensive components of the system.

Advantages of Power Transmission Belts

- Lowest cost means of transmitting power

- Ability to accommodate a wide range of speeds and center distance between driver and driven shaft

- Quiet and clean operation

- Require no lubrication like chains, gears and gearboxes

- Able to absorb shock loads and pulsations

- Can be used for special applications such as clutching and variable speed

Two Major Types of Power Transmission Belts

There are two major types of Power Transmission Belts. These are V-Belt and Synchronous Belt (also commonly referred to as timing belt).

Terminology

The terms “sheave” for v-belt drives and “sprocket” for synchronous drives and “pulley” (for all drives) are commonly used when referring to the “wheels” used connect the belt between the driver and driven units of different types of belt drives. The International Standards Organization (ISO) uses the term pulleys for all drives whether they are v-belt or synchronous.

V-Belt

The V-Belt is a friction device and works on the principle of the wedge. It relies on tension to create friction on the sidewall of the sheave to transmit power. It is non-synchronous and allows slippage. Slippage can be desirable and intended in drive design. For example, in a fan where the belt must slip rather than break the belt or bend a shaft if the blade contacts something or is blocked. V-Belts are the most basic belt utilized for power transmission and are generally speaking, also the most economical.

V-Belt Characteristics

- Less expensive than most other forms of power transmission

- Start, stop and run smoothly

- Operate noiselessly and without lubrication

- Absorb objectionable and harmful vibrations

- Clean and require minimum maintenance

- Rugged and long lasting

- Accommodate a wide selection of speed ranges

- Cover an extremely wide horsepower range

- Easy to install and simple to replace

- Relatively unaffected by moisture, abrasive dusts, or extreme variations in temperature

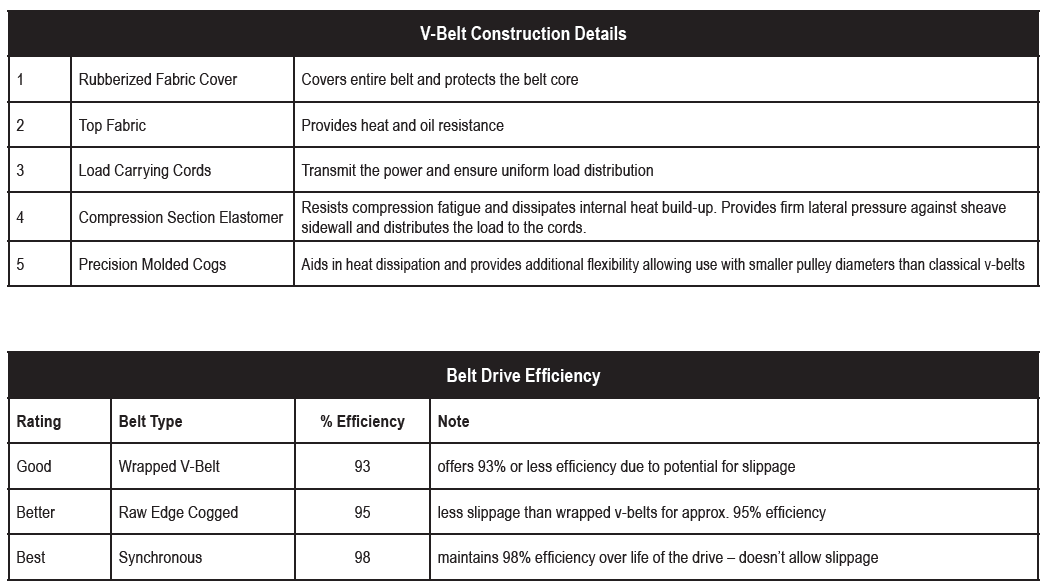

Two types of V-Belt Construction are Commonly used in Industry:

- Wrapped V-belt - has a protective fabric cover and will allow some slippage in peak torque situations. Slippage can be advantageous in some drives to avoid damage to belt and other drive components

- Raw Edge V-belt - has fabric on the top and bottom but no fabric on the “raw edge” sides. This construction resists slippage with more grip on the sheave sidewalls due to the exposed rubber sidewall that has no fabric as a wrapped v-belt does. It is advantageous in drives where minimum slippage, maximum efficiency and power transmission is required. It will still allow slippage but is more resistant to slippage than a wrapped v-belt.

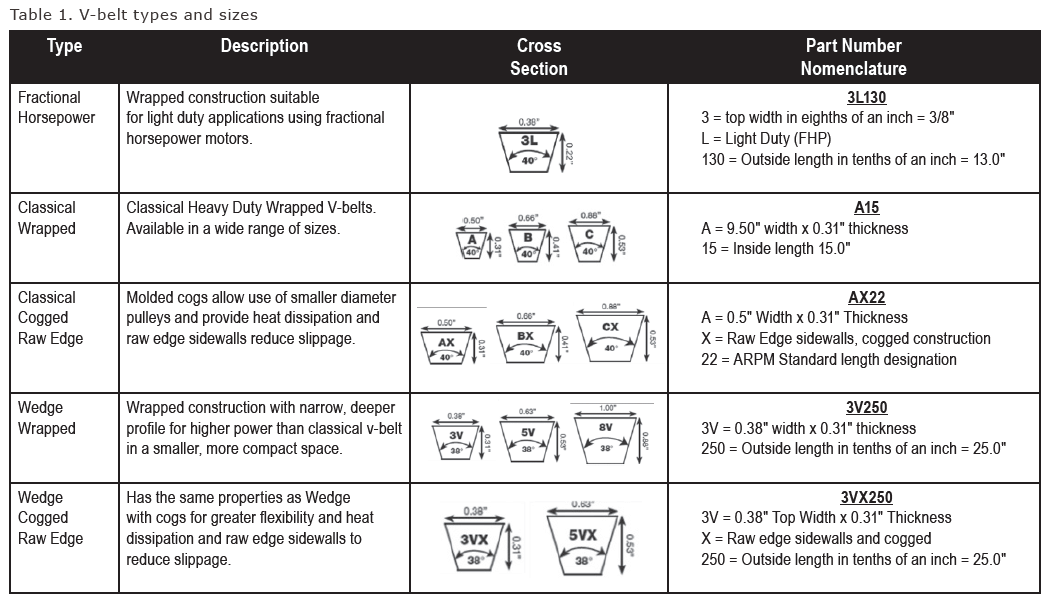

V-Belt Types and Sizes

V-Belts come in a wide variety of sizes and lengths. They are identified by their various cross sections and length.

The common types used in the HVAC-R industry are listed in the table below.

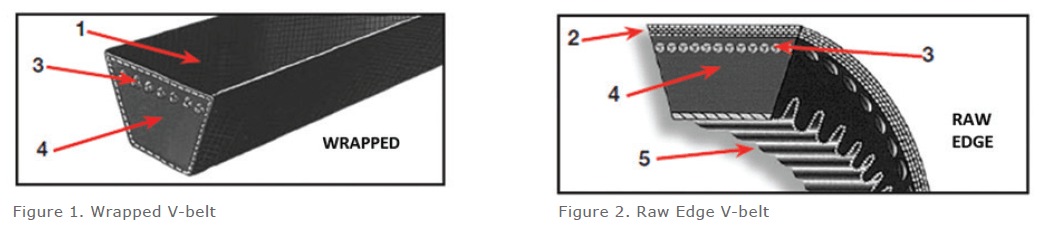

Synchronous Belt

Synchronous or timing belt is a positive engagement device and relies on the accurate meshing of the belt teeth with the sprocket grooves. It does not allow slippage. There are drives where slippage can cause damage and must be prevented. For example, the valve train of some internal combustion engines. If the drive does not maintain synchronous operation the piston can contact and damage the valves. Converting an HVAC V-belt drive to synchronous belt is a way to gain a significant efficiency increase and resulting energy savings.

Use a Synchronous Belt Drive when:

- High mechanical drive efficiency and energy savings are a priority

- Synchronous transmission and precision positioning between shafts is required

- Low maintenance is a priority

- High torque, low RPM requirements

- Compact drive layout is necessary

- Low noise requirements (compared to chain and gears)

- Environmental or contamination concerns (no lubrication required such as with chain)

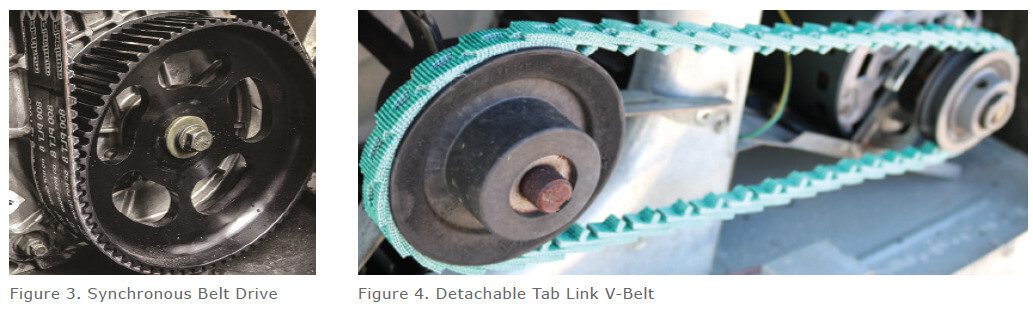

Detachable Tab Link Type V-Belt

Detachable Tab Link V-Belt is an ideal alternative to conventional rubber v-belts in many applications. Made endless by hand using no tools, an open length of belt can be assembled from tabs (like links in a chain) and wrapped around pulleys in hard-to-fit applications yielding fast belt replacement.

- For use in applications where it's difficult to install an endless conventional v-belt, avoiding costly labor-intensive machine disassembly.

- Ideal for use on mobile service vehicles where carrying a large inventory of v-belts is not practical. A long roll of detachable tab link type v-belt can be carried on the vehicle and any length of belt can be made versus carrying a large inventory of conventional v-belt sizes. Eliminates the possibility of being “out”” of a needed size.

- Can be used either as singles or on multiple v-belt drives. Widely used in HVAC, poultry, agriculture and general industry.

- Increased calls per day for mobile service vehicles (reduced labor cost and travel spent searching for the right v-belt)

- Less vibration and noise than conventional v-belts

Saving Energy with Efficient Belt Drives

The cost of energy in manufacturing has a major effect on overall cost of a product. In fact, energy cost is currently one of the main drivers in reshoring, the growing movement of bringing manufacturing operations back to the United States from offshore locations. By introducing energy efficient belts drives, you can implement a simple, cost-effective solution to achieve energy savings. Proper installation and maintenance combined with the latest drive belt technology can improve efficiency through reduced energy consumption and enhance drive performance.

Regular Maintenance - Synchronous and V-Belt Drives

Proper Tensioning - One third of electric motors employed in industrial and commercial applications use belt drives. The majority of these drives use wrapped (fabric covered) V-belts, relying on the friction between the belt and sheave groove to transmit power. Relatively inexpensive, wrapped V-belts are designed to allow for limited slippage; intended to slip only in potentially problematic situations, this slippage prevents damage to expensive driven equipment by acting as a safety fuse. The belt can slip or break rather than damaging the more expensive driven unit.

But without frequent periodic maintenance, these belt drives tend to slip excessively during normal operation and result in reduced efficiency and increased operating costs. A correctly installed wrapped V-belt drive can attain 95-98% efficiency soon after installation, rapidly declining to approximately 93% efficiency during the course of normal operation. Without continued periodic tensioning maintenance, efficiency will decrease even further and components will wear more quickly. Belt drive tensioning maintenance is often neglected due to higher maintenance priorities, meaning belt drives receive attention only when a belt finally breaks. This situation can be avoided by periodically adjusting the tension, increasing the lifespan of belts and reducing the frequency of service interruptions.

Proven Energy Saving Solutions

The U.S. Department of Energy recommends replacing V-belts with proven belt drive solutions, including cogged raw edge V-belts and synchronous belts, as best practice for increasing belt drive energy efficiency. Upgrading from a wrapped V-belt to a raw-edge cogged belt yields an average 2% increase in efficiency, a good return for a very low-cost investment. For new drives, using synchronous belts can provide an average 5% efficiency increase compared to V-belts. While increases of 2–5% may seem insignificant, when considering the energy cost savings over multiple

drives and longer running times, the savings soon become substantial. The following overview of the available belt options, as well as the pros and cons of each solution, is a useful guide for evaluating and selecting the best belt for the task.

Good: Standard Wrapped V-Belt - Typical Efficiency = up to 93%

The wrapped V-belt is typically the standard belt utilized in many applications. The excellent mechanical characteristics and high transmission efficiency make this type of belt a popular choice.

PROS

The wrapped V-belt will protect the drive from shock loads where torque spikes are present, by allowing some slippage and act as a safety fuse reducing risk of damage to valuable components.

- Any application where some slippage is desirable will be better suited to using a wrapped V-belt.

- A wrapped V-belt offers more protection against contamination as the cover offers protection to the rubber body of the belt.

CONS

Among available belt drive options, wrapped V-belts are the least efficient.

- This type of V-belt requires frequent tensioning to maintain its initial efficiency. If not properly maintained on a regular basis, it will lose up to 20% efficiency.

- There is a sharp reduction in efficiency after installation due to slippage, as the V-belt stretches during operation.

- There is a large variation in efficiency between V-belts, on multi-belt drives, tension variation between multiple belts can result in a belt that is not working as hard as the others, therefore impacting overall drive efficiency.

Better: Cogged Raw Edge V-Belt – Typical Efficiency = up to 95%

“Raw Edge” construction differs from wrapped v-belt in that it does not have external fabric on the sides of the belt. This puts rubber in direct contact with the pulley grooves greatly reducing slippage. The cogged raw edge V-belt also has notches cut in the underside for cooler operation and greater flexibility, making it ideally suited for smaller diameter pulleys. More efficient than a wrapped V-belt, it is the best choice where a synchronous drive is not cost-effective but greater efficiency is desired.

PROS

- The cogged or notched construction reduces bending resistance in the belt, so it is able to bend around smaller diameter pulleys than a wrapped V-belt. Smaller pulleys require less material to produce, meaning they are generally cheaper than larger versions.

- The raw edge sidewall construction (meaning no fabric cover) has a greater coefficient of friction than a wrapped V-belt, making it more slip-resistant and allowing it to transmit more power.

- A cogged V-belt runs cooler than a wrapped V-belt, and, as a result, will last longer. The US DoE estimates that this belt type is 2% more efficient than standard V-belts.

- This belt runs on the same pulleys as a standard V-belt, so upgrading is a simple process of changing the belt without incurring the cost of new components.

- Unlike a synchronous belt, a cogged V-belt provides better vibration damping where excessive vibration is a concern.

CONS

- Initial cost of raw edge v-belt is higher although return on investment is rapid.

Best: Synchronous Belt – Typical Efficiency = Up to 98%

Also known as “timing belt”, synchronous belt teeth engage with corresponding pulley teeth. This belt eliminates slippage and provides the highest efficiency. However, it is not a direct replacement for existing v-belt drives as it requires a new drive design that will require all new belts and pulleys.

PROS

- The teeth in a synchronous drive create positive engagement with the sprockets for zero belt slippage and maximum efficiency.

- A synchronous belt is the best choice for new drive applications, as the initial cost is offset against the increased efficiency and reduced downtime for maintenance that it offers.

- This belt maintains its efficiency over its lifespan, unlike a standard V-belt, which loses efficiency over time.

- This type of drive runs cooler and with less tension than V-belts, which extends the life of both bearings and belts.

- Capable of operating in wet and oily conditions that would hinder a V-belt, a synchronous belt requires only minimal maintenance and re-tensioning.

CONS

- Conversion of a v-belt drive to synchronous belt will require both new belts and pulleys, making it a higher initial cost than simply replacing v-belts on a v-belt drive.

- Synchronous belt generates more noise than V-belt.

- A synchronous drive is less suited for applications where some slippage is desirable.

- Alignment and tension is critical as synchronous belt is not as tolerant as a V-belt to misalignment.

Preventative maintenance

The implementation of a preventative maintenance program including proper belt drive installation, tensioning procedures and best practices will increase productivity, reduce downtime and yield the additional benefit of improved workplace safety.

The majority of power transmission drive problems are attributed to improper installation and maintenance. This article is intended to provide guidance in avoiding drive problems, extending drive life and maximizing performance while maintaining a safe working environment.

When compared to the cost of production downtime and the labor costs associated with a belt failure, the cost of a belt is relatively insignificant. Generally speaking, at any given production facility, 80% of the downtime related to power transmission belts can be found on 20% of the drives in the plant. In other words, 80% of the drives are fine. The remaining 20% are “problem drives” requiring frequent attention and replacement. Additionally, it’s not uncommon for a large industrial facility to spend thousands of dollars annually to determine what type of replacement belt is needed for a particular drive. Worn belts are often difficult to identify as their part numbers sometimes become impossible to read after lengthy service.

Safety

Power transmission products are potentially dangerous. Failing to follow recommended application information and procedures for installation, and maintenance of products may result in serious bodily injury or death. Make sure that product selected for any application is recommended for that service. Always follow the recommendations of the original equipment manufacturer. Contact Megadyne for specific information.

- Before doing any maintenance work on power drives, always switch off the power and lockout the drive. A tag should be attached stating, "Danger - do not operate."

- One should always try to operate the equipment after shutdown to make sure you have locked-out the proper switchbox, ensuring that the switchbox is operating properly and also to release any stored energy.

- Use belt guards to provide protection for personnel from contact with drive components. Never test or operate belt drives without guards in place.

- Always wear gloves to protect from sharp edges and hot surfaces.

- Never wear loose or bulky clothing in close proximity to an unguarded drive where it could become entangled in the drive and cause injury to personnel.

- Always be aware of pinch points where hands and fingers can be injured, especially where the belt enters the sheave or sprocket.

- Always keep the area around the drive free of clutter and debris.

- Never re-use damaged pulleys. They should be replaced if not repairable.

- Always use static dissipating belts in conjunction with industry approved methods to dissipate electrical charges on drives used in hazardous atmospheres.

- Never use Megadyne belts for aircraft applications. Megadyne belts are not designed for or intended for use on aircraft propellers, rotors or accessory drives. Do not use on helicopters or private, commercial, ultralight or any other airborne aircraft application.

Installation & maintenance

Most drives fail due to improper installation & maintenance.

(see Figure 1)

- Good installation & maintenance practices ensure…

- Longer belt life

- Lower maintenance costs

- Longer drive component life

- More efficient drive systems

- Energy savings

- Safe operation

- Increased productivity

- Reduced downtime

Belt installation

After correct installment and alignment of pulleys you can install the belts. Always move the drive unit, usually an electric motor mounted on an adjustable base, to decrease the drive center distance and create slack so you can easily slip the belts onto the pulleys without force. Never force belts onto a drive with a tool such as a screwdriver or a pry bar. Doing so will rupture the fabric cover or break the load-carrying cords inside the belt.

Proper belt tension

Proper belt tension is essential for maximum belt life and efficiency. Improper belt tension is the leading cause of premature belt failure and increased costs. Under-tensioned belts lead to slippage, overheating, excessive pulley wear, rollover and noise, all of which lead to higher maintenance costs and inefficient power transmission. Also, over-tensioning belts leads to premature wear of bearings, shafts and pulleys. The result is more frequent replacement of drive components and costly downtime. Proper tension is the lowest tension at which the belt won’t slip or jump teeth under peak conditions.

V-Belt belt tensioning

V-belt tensioning can be performed using a tension tester gauge using the procedure in Figure 2. After seating the belts in the sheave groove and adjusting center distance to take up slack in the belts, further increase the tension until only a slight bow on the slack side is apparent while the drive is operating under load. Stop the drive and use the gauge to measure the necessary force to depress the belt and deflect 1/64-inch for every inch of belt span (use center belt on multiple belt drives).

For example, a deflection for a 50-inch belt span is 50/64ths, or 25/32-inch. The amount of force required to deflect the belt should compare with the deflection forces noted in Megadyne technical manuals.

Best practices

Matching V-Belts. When using multiple grooved sheaves, be sure that all of the belts are the same brand. Always replace complete sets of v-belts even if only one is worn or damaged.

Proper alignment is essential for long belt life. Check belt alignment whenever you maintain or replace belts or whenever you remove or install pulleys.

- Select Correct V-Belts to match Sheave Grooves

- Don’t mix belt brands; stick with one manufacturer

- Don’t mix new & used belts

- Replace worn pulleys after 3 belt replacements

- To check for loose belts, put your fingertips in a sheave groove (after drive shutdown). If sheave is so hot you cannot comfortably keep them there, the belts have probably been slipping.

- Ideal tension is the lowest tension where belt will not slip under peak load.

- Over-tensioning will shorten belt and bearing life.

- Inspect drive periodically. Re-tension the belts if slipping.

- If belts slip, check for adequate tension and/or worn sheaves.

- Never apply “belt dressings” to belts. These compounds are usually made from a petroleum derivative and can have a destructive effect on rubber compounds and other components of the belt.

Author: Jason Industrial