Mitigating Corrosion-Induced Hardware Failures in Data Centers using Air Filtration Technology

May 14, 2025

Data and Energy

In the realm of web and social media, as well as cryptocurrency mining and online commerce, there is a growing need for data centers to store the vast amount of data supporting these online activities. Data centers operate continuously, 24 hours a day, 7 days a week, 365 days a year.

The average person at rest is estimated to emit 400 to 450 Btu/hour, while a single rack of IT equipment can generate between 17,060 Btu/hour (5 kW) and 102,360 Btu/hour (30 kW). This, in turn, contributes to the overall increase in electricity consumption. Projections indicate a 12% annual growth in electricity usage in data centers 1.

A significant portion of the energy used in data centers is attributed to the compressor-based cooling. With the rising cost of electric power and a focus on reducing operational expenses, there is a growing trend among data center designers to employ direct outside air for cooling IT equipment. This approach is increasingly seen as a viable alternative to traditional chilled-water cooling, particularly in various environments. Some studies propose that utilizing outside air for cooling can result in energy savings ranging from 20 to 30% compared to a closed data center that relies less on outside air 2.

Corrosion in Data Centers

The growing adoption of outside air for data center cooling raises concerns about potential damage to metallic components. Issues such as copper creep corrosion or silver termination corrosion on circuit boards, caused by gaseous pollutants, are known risks. The 2009 ASHRAE particulate and gaseous contamination white paper recommended that copper and silver corrosion rates should be less than 300 Å/month to minimize the impact of corrosion on IT equipment reliability 3.

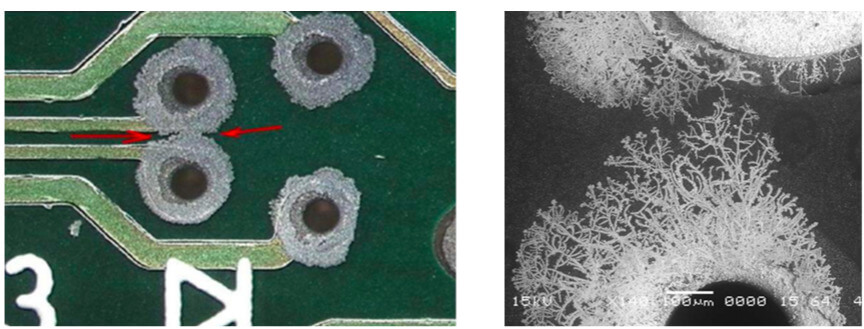

FIGURE 1: A visual representation illustrating:

First Image: Copper Creep Corrosion- Photographic and electron microscopic images depicting the degradation of copper plating on printed circuit boards as it transforms into copper sulfide. This progression extends across the boards, resulting in electrical shorts between nearby features and ultimately culminating in system failures 4, 6.

Second Image: Silver Termination Corrosion- Electron microscopic depicting the silver terminations in surface-mounted components resulting in the degradation of silver metallization and the eventual occurrence of open circuits in components such as resistors 5, 6.

Air Handling in Data Center

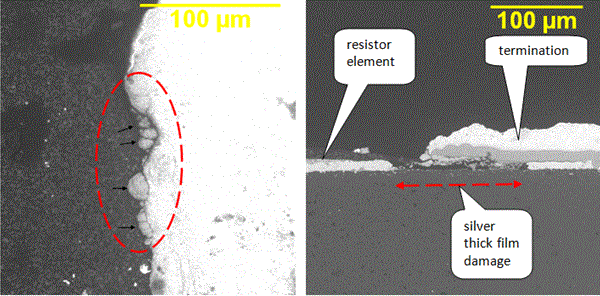

Data centers utilize air filtration systems that differ from conventional setups. They incorporate specialized units like the Computer Room Air Conditioner (CRAC) / Computer Room Air Handler (CRAH), housing filters along with fans, and cooling coils to ensure consistent room filtering. They are specifically designed to cool and regulate the temperature and humidity in the data center. Additionally, a standard Air Handling Unit manages incoming air from outside. Figure 2 illustrates the air handling system within a data center.

FIGURE 2: Illustration depicting the air handling system within a data center

Mitigation of Particulate Contamination

Effective particulate contamination control can be achieved with commonly available filters. ASHRAE recommends continuous room air filtering using MERV 8 filters, and suggests higher filtration levels like MERV 11 or MERV 13 for incoming air. Due to the energy-intensive nature of data centers, filters with low pressure drop and high dust holding capacity are preferred. Recently, Nanofiber filters, featuring thin layers on supportive substrates, have gained attention for their surface loading, which allows for effective dust accumulation. While in contrast, traditional filters experience depth loading over time, leading to blockages and increased pressure drops3.

Mitigation of Gaseous Contamination

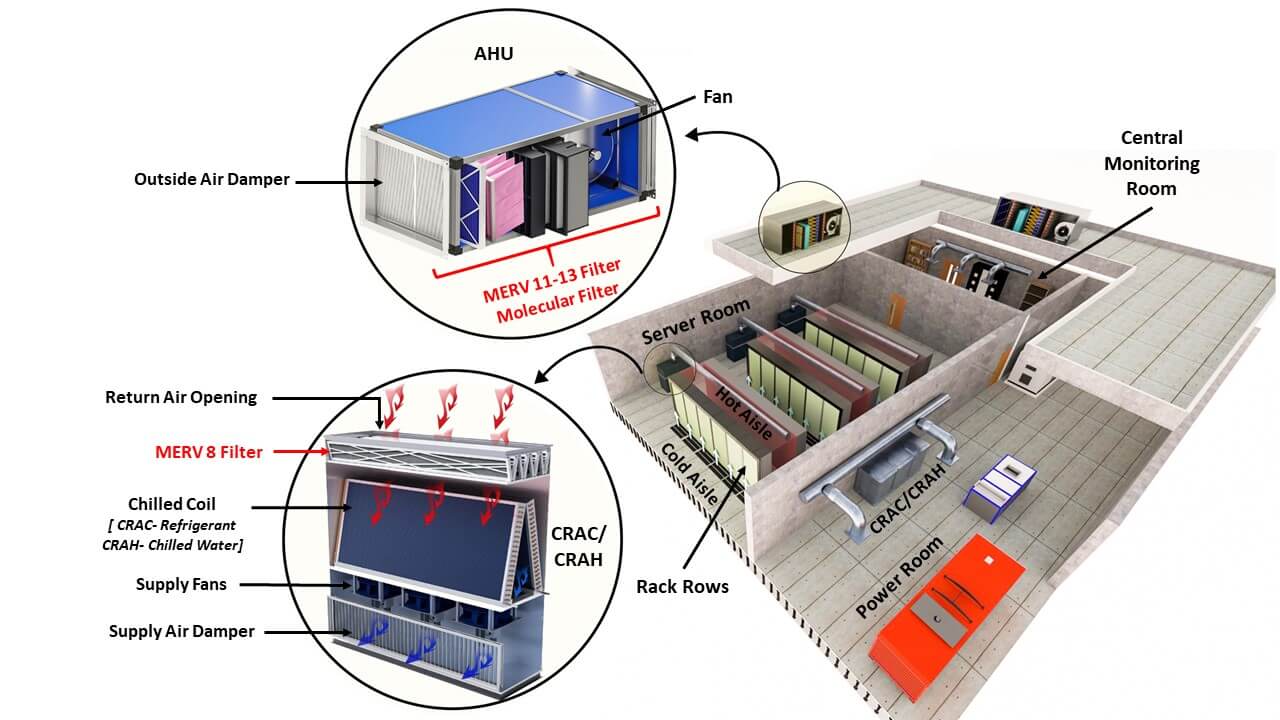

To manage gaseous contamination, specialized filters called molecular filters are used. In data centers situated in areas with high gaseous contamination, it is recommended to deploy molecular filtration systems for both incoming and internal air. Table 1 outlines gaseous elements present in the environment, highlighting potential threats to data center components if they exceed specified control limits.

TABLE 1: Gaseous elements present in the environment and their impact on data center components when surpassing specified control limits6.

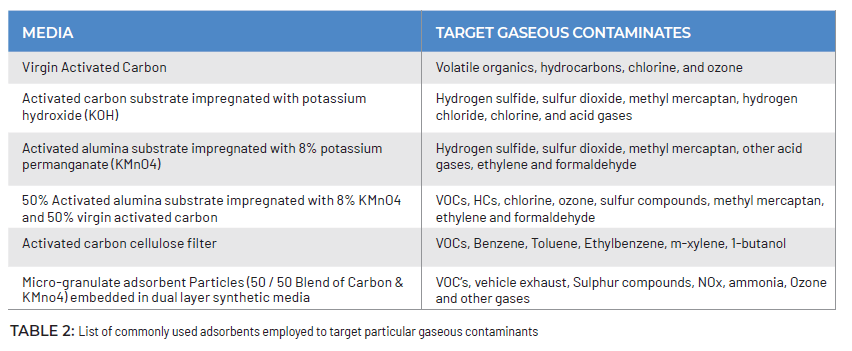

Molecular filters utilize adsorbent or chemisorbent media designed to capture gaseous contaminants. Depending on system design and contaminant characteristics, the media can be in the form of pellets, granules, or modules. Adsorbents, attracting molecules through forces like van der Waals forces, effectively capture low concentrations of non-reactive gases such as volatile organic compounds (VOCs), odors, and hydrocarbons. Activated carbon, with its extensive surface area, is a commonly used adsorbent capable of adsorbing a wide range of gases.

Chemisorbents chemically react with contaminants to form stable compounds, suitable for removing high concentrations of reactive gases like acids, bases, oxidants, and corrosives. Impregnated activated carbon, treated to enhance reactivity, is a frequently used chemisorbent in molecular filtration7. Some molecular filtration systems optimize performance by combining adsorbents and chemisorbents. For example, a system may use an adsorbent layer followed by a chemisorbent layer to eliminate both VOCs and acids from the air stream. Table 2 outlines various adsorbents widely used to address specific gaseous pollutants. Numerous ongoing studies are being reported aimed at developing new adsorbent materials with significant adsorption capacity.

When selecting a molecular filtration system for a specific application, several factors come into play, including the type and concentration of gaseous contaminants, the required airflow rate and pressure drop across the system, the desired removal efficiency and outlet concentration of contaminants, the operating temperature and humidity conditions, as well as the available space and budget for system installation and maintenance.

References:

- Steve Greenberg, Evan Mills, and Bill Tschudi, Peter Rumsey, Bruce Myatt, Best Practices for Data Centers: Lessons Learned from Benchmarking 22 Data Centers, 2006, ACEEE Summer Study on Energy Efficiency in Buildings, 3, 76-87.

- Henry C. Coles, Taewon Han, Phillip N. Price, Ashok J. Gadgil and William F. Tschudi, Air Corrosivity in U.S. Outdoor-Air-Cooled Data Centers is Similar to That in Conventional Data Centers, 2011, Lawrence Berkeley National Laboratory, 1-29.

- ASHRAE, Gaseous and Particulate Contamination Guidelines For Data Centers, 2011

- What is Creep Corrosion and How to Avoid or Mitigate It? (URL: https://knowledge.ni.com/KnowledgeArticleDetails?id=kA00Z000000kIpsSAE)

- Craig Hillman, Joelle Arnold, Seth Binfield, Jeremy Seppi, Silver And Sulfur: Case Studies, Physics, And Possible Solutions,2007, DfR Solutions, 1-13.

- Chris Muller, What’s Creeping Around in Your Data Center?, 2010, ASHRAE Transactions, 1-15.

- Jones, G., Rohrbach, R., Unger, P., Bause, D. et al., Wicking Fiber Chemisorption for Air Quality Improvement, 1997, SAE Technical Paper 970555,1-7.

Author: M.S.Giri Nandagopal, PhD, Product Development Engineer, Excelair Filters, Century Mechanical Systems Factory LLC