How do I Best Filter My Recycled Dust Collector Exhaust?

May 14, 2025

A Glimpse Into the Standard Setting Process of the new NFPA 660 Consolidated Standard for Combustible Dusts

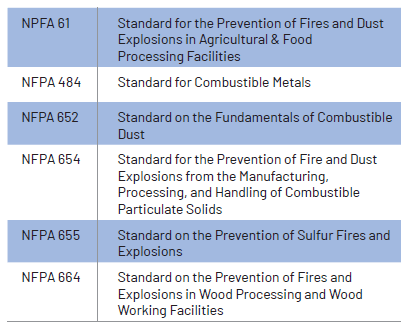

The National Fire Protection Agency (NFPA) standard on the appropriate media to use when recycling indoor air from dust collectors is a topic that just begins to scratch the surface on some of the challenges the standards development agency has faced during its current process of merging six separate NFPA combustible dust standards into one comprehensive standard, NFPA 660 Standard for Combustible Dusts, which is set to be released in early to mid 2025. This article will share some insight on this standard setting process through a close up look on the specific standard of the recycling air indoors from dust collectors. The six standards set to be consolidated are the following:

NFPA was founded in Quincy, MA in 1896 and for more than 125 years has been writing safety standards with the primary mission to help save lives and reduce loss. This has been accomplished through the development of safety code by the expertise of its more than 250 committees and over10,000 global volunteer committee members. These members include architects, analysts, engineers, government officials, manufacturers, first responders, and many others. The national electric code (NEC) is one of many standards that NFPA authors and maintains. 1.

Six separate combustible dust standards have been independently published for many years, with the first NFPA standard on combustible dust dating back to the early 1920’s in response to a series of fatal combustible dust accidents in the agricultural and food processing industries. Through the years, these independent standards became harder and harder for users to navigate and apply consistently. Approximately 5 years ago, a decision was made to begin a merge process with the objective to make easier the application of the standards to reduce risk of often fatal accidents involving combustible dust explosions 2.

Consolidating these standards has been a herculean task, consuming its many volunteer committee members now for years. This effort has included analyzing, combining, and debating hundreds of pages of guidance across the six standards on combustible dust safety. The distillation process of many years of effort and hard-fought advances in combustible dust safety has been challenging to say the least.

An example of one topic in particular that demonstrates the challenge of creating shared language around a single standard has been the guidance involving the indoor recycling of exhaust air from dust collectors. The benefits of recycling filtered air from a dust collector are clear:

- No reconditioning of air required. This amounts to a significant amount of cost savings through saving energy to heat or cool replacement air, particularly in more variable climates.

- No burdensome permitting required. Exhausting outdoors in most if not all municipalities requires facilities to go through an air permitting process. Depending on the local, state, and national regulations where the facility is located this can be quite onerous, expensive, and time consuming for organizations to endure.

- No pressure re-balancing required. Exhausting large amounts of air creates unwanted negative pressure inside facilities that needs to be balanced with additional air. If the amount of air being exhausted outside a facility varies over the course of operations, this becomes an ongoing operational challenge.

The hazards of recycling exhaust air from a dust collector are also clear – when filtering combustible dust in a dust collector, there is considerable risk of creating an explosive environment if the dust collector equipment and its respective integral filtration is not properly managed and consistently monitored by operators. A few of those risks include:

- Fugitive dust accumulation. An over-accumulation of combustible dust inside a collector due to not properly managing filter changes can quickly result in an abundance of fuel that, when dispersed, could easily result in an explosive dust cloud.

- Filter breach. If filters are not properly installed or managed, a filter breach can occur. This could cause combustible dust to bypass the filter and then be widely exhausted back into a facility. This dust cloud dispersion is a key ingredient in the recipe for a deflagration or explosion event.

- Miscalculation of particle size. If the application being addressed is producing particles smaller than the efficiency of the filter, this could result in small explosive particles making their way through the filter media and being exhausted back into the facility, with similar potential results as the bypass event cited in #2.

When it comes to the most effective way to specify the level of cleanliness of filtered air prior to recycling back into a facility from a dust collection system, the existing six standards offer conflicting guidance. The question is clear – what should the commonly accepted level of filtration become for the new consolidated NFPA 660 to best ensure the safety of recycled air from from dust collectors?

A task group was created and the scope defined. Our objective was to determine the best common language across the six standards that would guide users of the standard to understand how to approach handling this important facility management decision when selecting and managing dust collection systems.

The most compelling idea put forth by a task group member was to use widely accepted MERV values 3. as a way to guide users towards the most efficient and safe approach to appropriately size filtration prior to recycling air. MERV relates to filter efficiency and could be matched to the related particle size of the material being processed to allow for maximum capture of the particular combustible dust being generated. Using common language that incorporated MERV makes a lot of sense – but unfortunately we could not gain consensus on its use within our task group.

Ultimately, we decided to use more general language that leads users to refer to the “applicable industrial hygiene exposure limits” – based on the particular application in question and materials being processed. This approach felt like a compromise. While the applicable industrial hygiene exposure limits often are very stringent, my belief is that the universally known MERV ratings are much more accessible, easier to digest, and straightforward to apply. Task group members felt like the use of MERV more applied to HVAC and not dust collection, and that the potential to overlook combustibility concerns was present if we used MERV.

At the end of the day, we achieved what we set out to do – establishing common language in the new NFPA 660 that provides guidance on how to approach filtration of recycled exhaust air from a dust collector. What was also learned was that consensus and common decision-making when developing standards is often challenging, slow process. The goal, however, of keeping facilities safe and giving users a guide to do so has been maintained. If you encounter combustible dust in your environment, keep an eye out for the release of 660 coming soon to your local code enforcement officials.

Footnotes:

- National Fire Protection Agency, https://www.nfpa.org/About-NFPA

- Dust Safety Science, https://dustsafetyscience.com/nfpa-660-standard-for-combustible-dust/

- United States Environmental Protection Agency, https://www.epa.gov/indoor-air-quality-iaq/what-merv-rating

Author: Dan Prather, President of DualDraw, LLC